1. In order to ensure the good performance of the cooling system of mechanical equipment, all components of the cooling system should be thoroughly cleaned, tightened and lubricated, and the scale in the cooling system should be cleaned as much as possible (including the removal of scale in the radiator).

2. Check the water pump and fan drive belts. If the belts run for a long time, they will become tired and deformed, which will reduce the cooling effect. When replacing the belt, pay attention to the model and length, and adjust its tightness correctly.

3. Check the water tank connecting hose. The water tank hose has poor oil resistance and is prone to early damage, thus affecting the water supply and causing the engine temperature to be too high. At the same time, check whether there is sufficient cooling water and add it in time if it is insufficient.

4. Pay attention to the reading of the water temperature meter. When it reaches above 90°, measures must be taken. You can choose to park in a nearby cool place and cool down at idle speed. Be careful not to turn off the engine immediately to avoid overheating inside the engine and causing accidents such as cylinder pull. After the temperature drops, you should also check the tension of the fan belt.

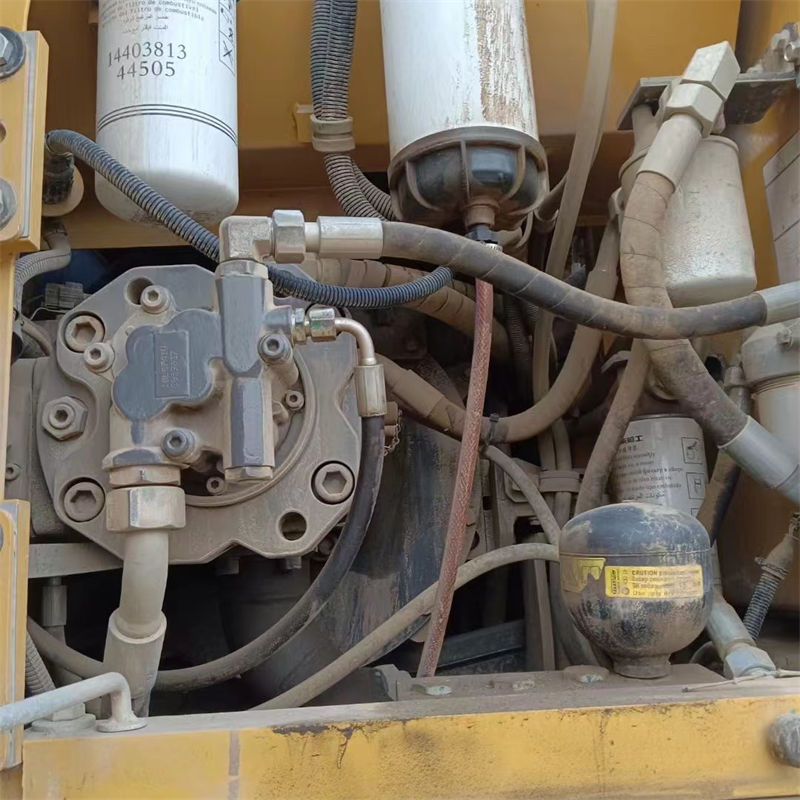

5. Conduct a targeted performance test on each component of the lubrication system to ensure accurate indications on the oil pressure gauge and gearbox pressure gauge. Stop the oil supply in the gearbox, pitch converter and drive axle, conduct a systematic inspection, from the quality of the oil to the quantity of the oil, and keep the oil clean.

If you need to buy excavator accessories, XCMG excavators or other brands of second-hand excavators, you can consult us at any time.

Post time: Apr-25-2024